University engineers to produce final prototype mirror for world’s largest telescope

Date: Wednesday, July 31, 2024

Engineers from Glyndwr Innovations Ltd (GIL) – a wholly-owned subsidiary of Wrexham University – are producing the final prototype mirror for the world’s largest telescope.

The team based at the OpTIC Technology Centre, located at the University’s St Asaph campus, have signed their latest contract with the European Southern Observatory (ESO) for the production of ESO’s Extremely Large Telescope (ELT)’s M5 commissioning mirror.

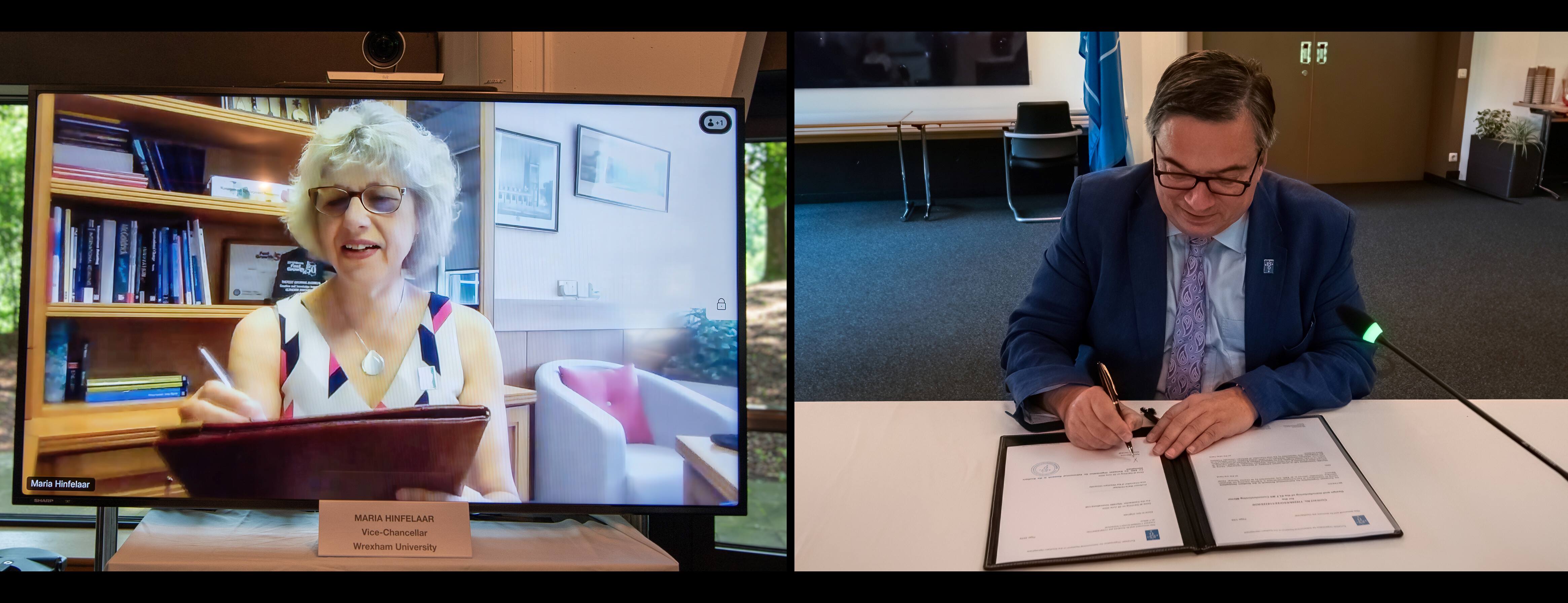

The contract signing took place at ESO’s headquarters in Garching, Germany – with remote participation from the UK, including Professor Maria Hinfelaar, Vice-Chancellor at Wrexham University. The signing signals the telescope taking another step successful towards completion.

ESO is building this groundbreaking telescope on Cerro Armazones mountain, situated at 3,046 meters above sea level in Chile's Atacama Desert.

The telescope will feature a colossal 39-metre main mirror (M1) which is composed of 798 individual hexagonal segments, making it the largest telescope in the world for both visible and infrared light. It incorporates an advanced five-mirror optical system designed to view the universe with unparalleled clarity.

Each of the ELT's mirrors (M1, M2, M3, M4, and M5) has unique shapes, sizes, and functions, working together seamlessly to deliver superior observational capabilities.

The engineering team at GIL have had long-term involvement in the ELT project since they helped develop the manufacturing processes for the M1 mirror segments optimising the process so that the mirrors could be produced to the required specification at the necessary delivery rates.

The M5 mirror is a crucial part of the ELT’s adaptive-optics system design: it will adjust its position up to 10 times per second without bending to allow the telescope to obtain the sharpest possible images. Like the rest of the ELT, M5 is pushing technology to its limits – at 2.7 by 2.2 metres and weighing approximately 400 kg, it is the largest tip-tilt mirror ever produced.

Since such a large silicon-carbide mirror, with such strict polishing requirements, has never been produced before, there are risks associated with manufacturing it which could possibly delay the ELT project schedule.

To ensure that the ELT is ready to observe the skies before the end of the decade, ESO has partnered with Glyndwr Innovations to create an alternative M5 mirror, called the M5 commissioning mirror, to be used to commission the telescope and demonstrate its performance prior to the installation of the silicon-carbide M5 mirror.

Dr Ian Barwick, Head of Operations at Glyndwr Innovations, praised the Glyndwr Innovations team for their “extraordinary efforts and capability”.

He said: “We are extremely pleased to have secured this latest contract with ESO to supply an M5 commissioning mirror for the ELT. This M5 commissioning mirror, part of the ELT’s optical system, helps stabilize images against vibrations and wind, enhancing image quality.

“We have been working with ESO for more than a decade now, so we are delighted to continue to meet their needs as part of this incredible – but also challenging – project. I’d like to take this opportunity to pay tribute to our talented team of engineers for their extraordinary efforts and capability.

“It’s a remarkable project to be a part of – and further enhances our world-class reputation.”