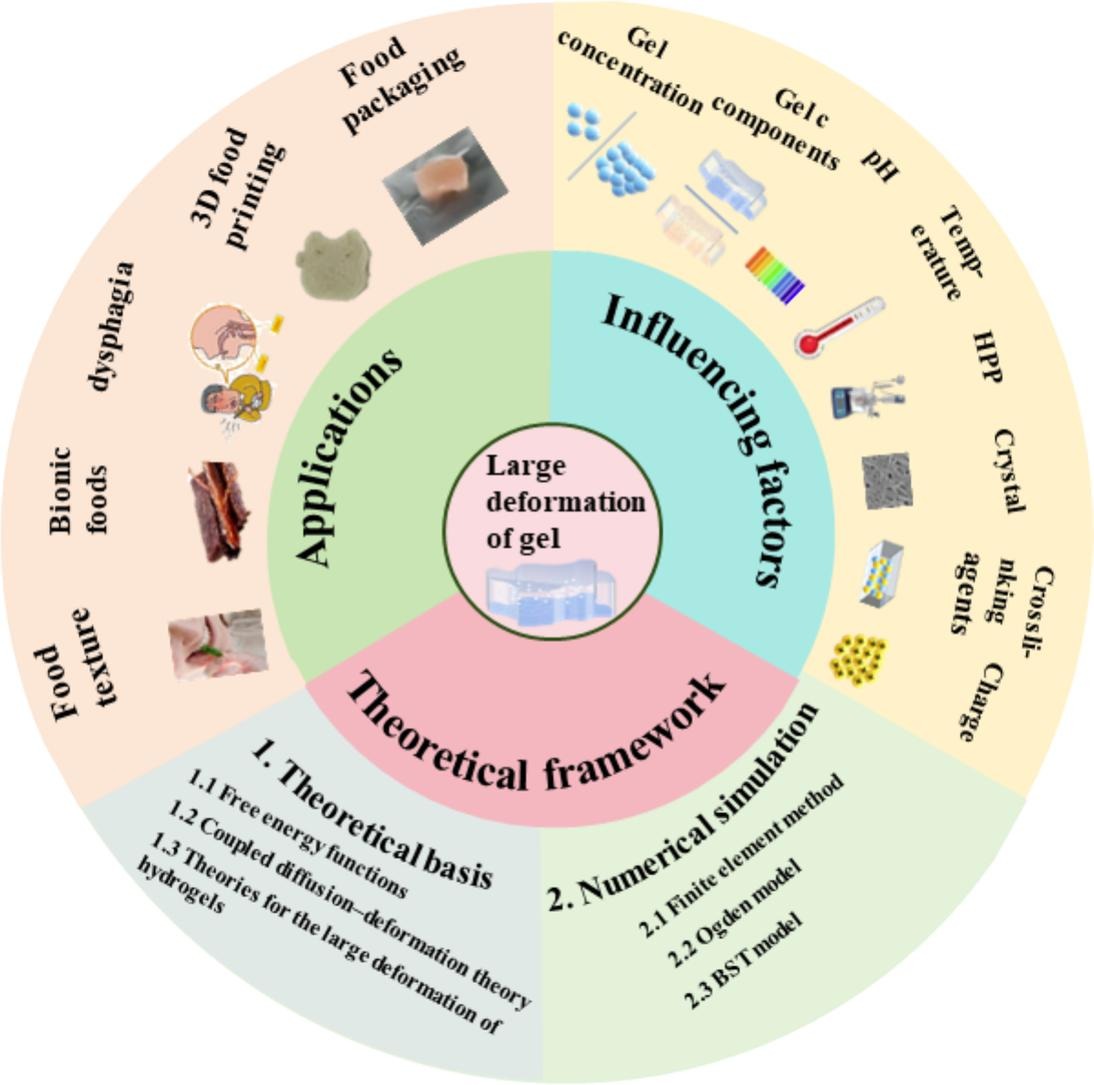

Factors, theories, models, and applications of food gels

March 2025

Dr Jixin Yang and colleagues recently published a review:

"Large deformation of food gels: Influencing factors, theories, models, and applications—A review"

Gel Deformation and its Applications

Gels are versatile materials used in food science, medicine, and various industries due to their unique structural properties. Understanding how gels deform—whether they stretch, compress, or bounce—is crucial for designing products in areas like food, healthcare, and robotics. This review highlights the main factors influencing gel deformation, including concentration, pH, temperature, pressure, crystallisation, and crosslinking agents.

Factors Affecting Gel Deformation

Gel Concentration

The concentration of gel-forming materials like gelatin, agarose, and starch directly influences gel properties. Higher concentrations lead to firmer gels, while lower concentrations result in softer, more elastic gels. These changes affect how gels deform under stress, with stronger gels having more resistance to deformation. For instance, in food, a firmer gel provides a better texture for products like gummy candies, whereas a softer gel is ideal for products like puddings.

pH and Temperature

Both pH and temperature significantly impact gel formation and behaviour. Temperature can affect the stability of protein networks, as seen in meat gels, where preheating at 90°C improved strength and elasticity (Mad-Ali et al., 2018). Similarly, pH influences starch gels and gelatin, altering their structure and stability. While the effects of pH and temperature on gel properties are well-documented, their combined effects on mechanical stress and large deformations are still not fully understood.

High-Pressure Processing (HPP)

High-pressure processing (HPP) is a non-thermal method that improves gel stability without compromising food quality. By applying pressures between 100 to 1000 MPa, HPP enhances protein-polysaccharide interactions and can reduce gelatinisation temperatures, improving the texture and elasticity of gels. For instance, HPP-treated crabmeat gels showed increased flexibility, while Tai Lake whitebait gels exhibited significantly higher strength (Velazquez et al., 2021).

Crosslinking Agents

Crosslinking agents such as transglutaminase (TG) and oxidases create strong covalent bonds between molecules, improving gel stability. These agents can be used in food production and biomedical applications to create more durable gels. For example, a system using whey protein and papain (Liu et al., 2023) demonstrates the potential of crosslinking to customise gel properties for various applications.

Crystals and Gel Properties

Crystallisation in gels occurs as they age, leading to structural changes. While crystals can improve gel strength, excessive crystallisation can make gels brittle. Adding materials like cellulose nanocrystals can improve water retention and strength, as seen in whey protein gels (Xiao et al., 2020). Controlling crystallisation is key to maintaining desirable gel properties.

Applications in Food and Health

Food Texture

Food texture, or "mouthfeel," is crucial in determining how we perceive food, especially when it comes to gels. The way gels break down when we bite into them affects our eating experience. Softer gels are ideal for desserts, while firmer gels are more suitable for gummies or meat alternatives. Tools can measure the force required to break a gel and how much it stretches, both of which influence texture (Franks et al., 2020).

3D Food Printing

3D food printing is an emerging technology that allows for custom-designed foods. Gels used in 3D printing must be able to withstand the stress of passing through the printer nozzle while maintaining their shape after printing. This capability is important for creating personalised food products. Advances in this area include developing gels with adjustable fluidity and elasticity to improve printing success and nutritional value (Umeda et al., 2024).

Dysphagia-Friendly Foods

Dysphagia, a condition that makes swallowing difficult, requires foods that are soft and easy to swallow. Gels are well-suited for this purpose because they can be modified to have low fracture stress, making them easy to break down while chewing. Modifying gel properties with additives can ensure that they are safe and comfortable for individuals with swallowing difficulties (Štreimikytė et al., 2020).

Bionic Foods

Bionic foods use gels to replicate the texture and characteristics of natural foods like meat. These plant-based alternatives are gaining popularity as they provide a more sustainable option for consumers. By adjusting the deformation properties of gels, such as elasticity and toughness, bionic foods can mimic the fibrous texture of meat (Du et al., 2023a). This innovation is helping to address dietary needs and environmental concerns.

Food Packaging

Hydrogels are also being used in food packaging to control moisture levels, which helps extend the shelf life of food. These gels can be made from natural materials, offering a sustainable and effective solution for food preservation. They need to be strong enough for handling and flexible enough to form tight seals. By adjusting the properties of hydrogels, manufacturers can create the perfect balance of strength, flexibility, and moisture retention (Ahmed et al., 2013).

Conclusions

Gels play a crucial role in food science, enhancing texture, taste, and stability. By understanding how different factors influence gel deformation, we can create better products for a range of applications. However, challenges remain, particularly in predicting how gels behave when eaten, as current models don't fully account for the complex processes involved in chewing and digestion. Future research should aim to integrate real-world data with theoretical models to improve the customisation of gels, especially for emerging technologies like 3D food printing and for people with swallowing difficulties. Additionally, sustainable innovations in gel production, such as bio-based crosslinkers, will be important for making gel-based solutions more environmentally friendly and scalable.