PhD Research in the Spotlight

Andrew Sharp, is a Senior Lecturer in Electrical Engineering here at Wrexham University and Andrew is in the fifth year of his postgraduate research studies.

Andrew’s research is on Temperature Gradient Improvement of Power Semiconductor Modules Mounted on a Forced Air Heat Sink, and he is planning on submitting his thesis for his PhD in 2026. Last academic year, Andrew successfully secured funding which enabled him to purchase sensors, manufacture Printed Circuit Boards (PCBs) and enhance the design of the test-rig. Below is an overview of the research undertaken by Andrew and the results to date.

Background Information

- It has been reported that about a third of total component failures in power electronic devices occur due to the failure of power semiconductors.

- Passive and forced air-cooled heat sinks are considered effective and inexpensive solutions, widely used in industrial installations and are typically a block of aluminium with fins cut into the bottom, to transfer heat away from the semiconductor device.

- In the case of forced air cooling, a fan is located at one side of the heat sink to provide airflow through the fins.

- Such a heat sink configuration causes a temperature difference (gradient) along the length of the heat sink.

- A high temperature gradient creates mechanical stress in the structure of the semiconductor, and it has a negative impact on the reliability of operation and the lifetime of the module.

- The Aim of my PhD research is to propose a solution by making a simple modification to a standard heatsink to result in an even distribution of temperature across the heatsink, reducing the thermal-mechanical stress on the semiconductor components and thus preventing premature failure.

Methodology

Modelling and simulation of heatsinks using ANSYS software, with simulation results being validated by physical temperature readings.

One method is to make a v-cut in the fins of the heatsink:

.png)

Figure 1 - v-cut in heatsink fins

Another method is to make a wedge-cut in the fins of the heatsink:

.png)

.png)

Figure 2 - wedge cut in heatsink fins

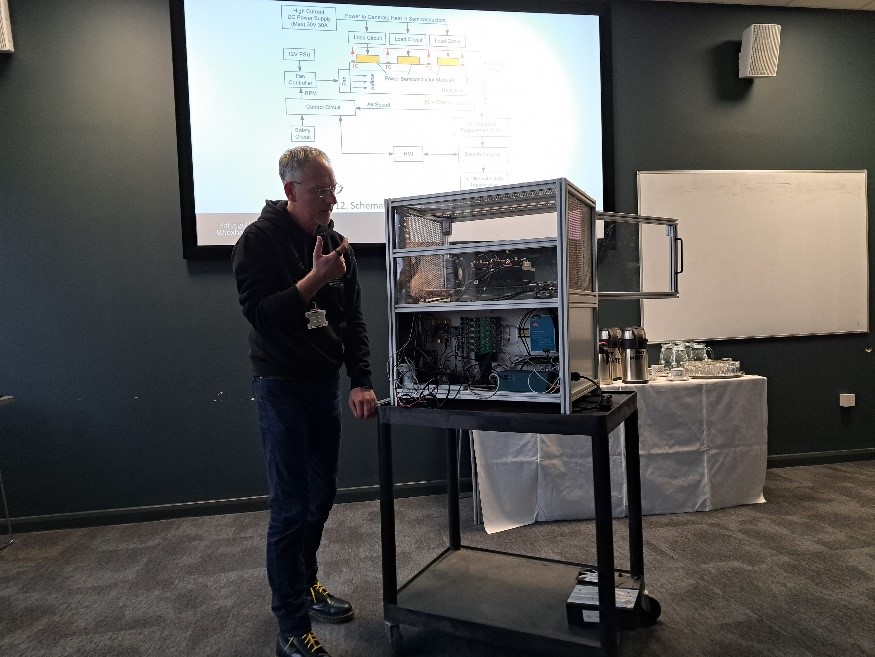

Simulation Results are validated by temperature measurements taken on a bespoke test-rig that has been specially designed and build and manufactured for this research.

.png)

.png)

Figure 3 - heatsink temperature measurement test-rig

Results

.png)

.png)

Figure 4 - Uneven temperature distribution and even temperature distribution

It can be seen from Figure 4 that to achieve a more even temperature distribution that the method that I am proposing seems a bit counter-intuitive in that it involves raising the lowest temperature to equal the highest temperature.

However, this is acceptable as long as the maximum temperature reached does not exceed the rated temperature of the semiconductor device.

For the power electronic modules having a large area of the semiconductor structure, the temperature gradient becomes a more important reliability issue than the maximum temperature.

Research Publications and Output

A.Mueller, C. Buennagel, S. Monir, A. Sharp, Y. Vagapov and A. Anuchin, “Numerical Design and Optimisation of a Novel Heatsink using ANSYS Steady-State Thermal Analysis,” in Proc. 27th Int. Workshop on Electric Drives (IWED), Moscow, Russia, 2020, pp. 1-5,

C. Bünnagel, S. Monir, A. Sharp, A. Anuchin, O. Durieux, I. Uria, and Y. Vagapov, “Forced air cooled heat sink with uniformly distributed temperature of power electronic modules,” Applied Thermal Engineering, vol. 199, Nov. 2021, Art no. 117560

A.Sharp, S. Monir, Y. Vagapov and R. J. Day, "Temperature Gradient Improvement of Power Semiconductor Modules Cooled Using Forced Air Heat Sink," 2022 XIV International Symposium on Industrial Electronics and Applications (INDEL), 2022, pp. 1-5

A. Sharp, S. Monir, R. J. Day, Y. Vagapov and A. Dianov, “A test rig for thermal analysis of heat sinks for power electronic applications,” in Proc. 19th IEEE East-West Design & Test Symposium (EWDTS), Batumi, Georgia, 22-25 Sept. 2023, pp. 1-4,

Future Publications:

Paper accepted for conference and will be presented in November 2024:

“Numerical Optimisation of Air-cooled Heat Sink Geometry to Improve Temperature Gradient of Power Semiconductor Modules”

Links to the curriculum

This research has fed into many students undergraduate and postgraduate projects, in the areas of:

- ANSYS simulation-based projects such as modelling of heatsinks.

- Electronic design for the temperature test-rig, such as designing circuits to make temperature measurements, design and fabrication of a safety cage, regulating the power dissipation through the semiconductor devices.

Some of these students have been included in the list of authors on the publications listed above.

Links to Industry

Invertek Drives, located in Welshpool, have donated a selection of heatsinks for use in this study.

Supervisory Team

Principal Supervisor – Dr. Yuriy Vagapov

Secondary Supervisors – Prof. Richard Day, Dr. Shafiul Monir, Dr. Mobayode Akinsolu